- 產品詳情

- 參數視頻

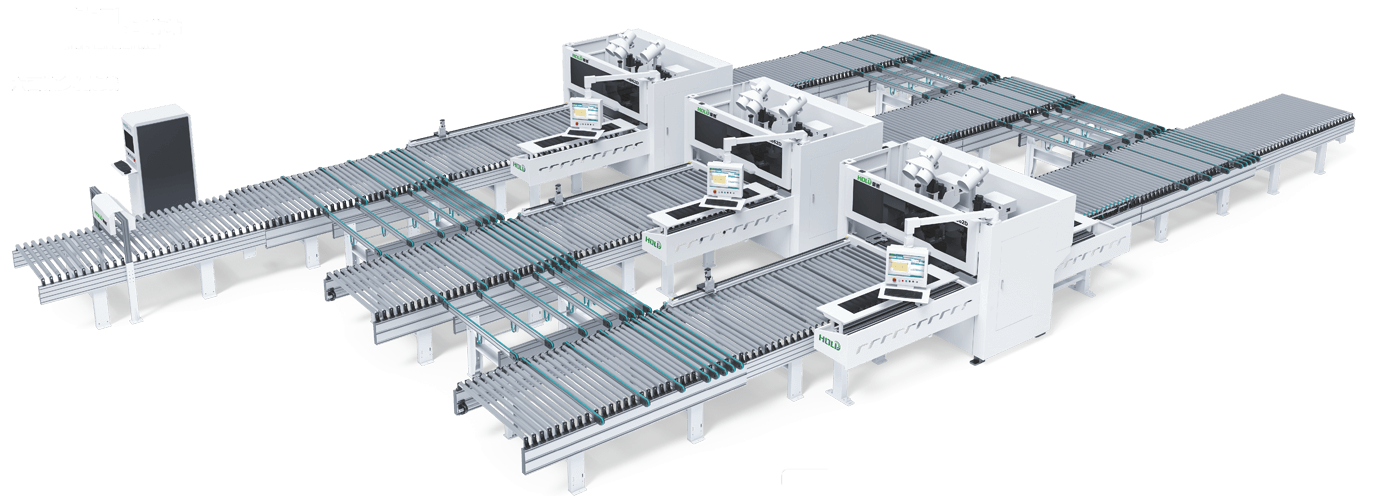

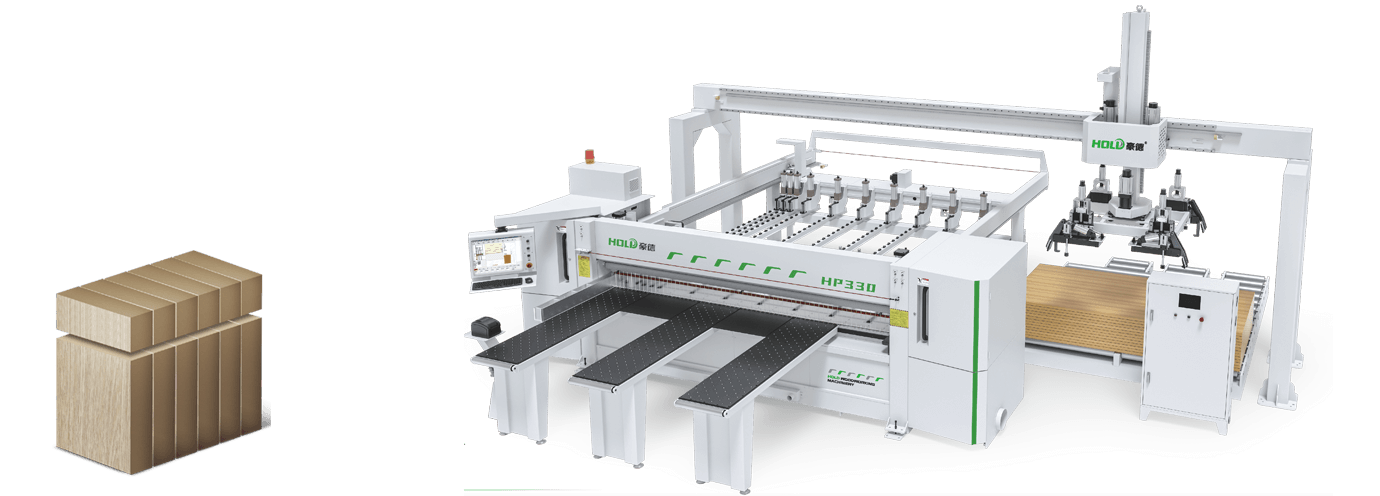

智能連(lian)線生產,吸(xi)盤可自動旋轉縱向或橫向上料

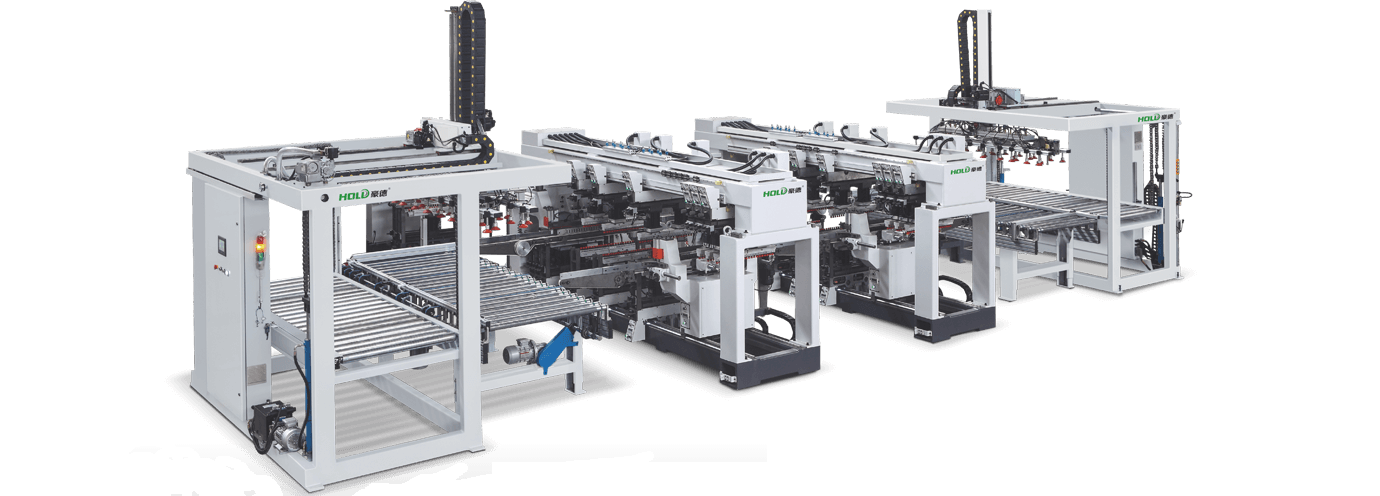

自動抓板(ban)上料,降低勞動強度,減少(shao)大工(gong)成(cheng)本

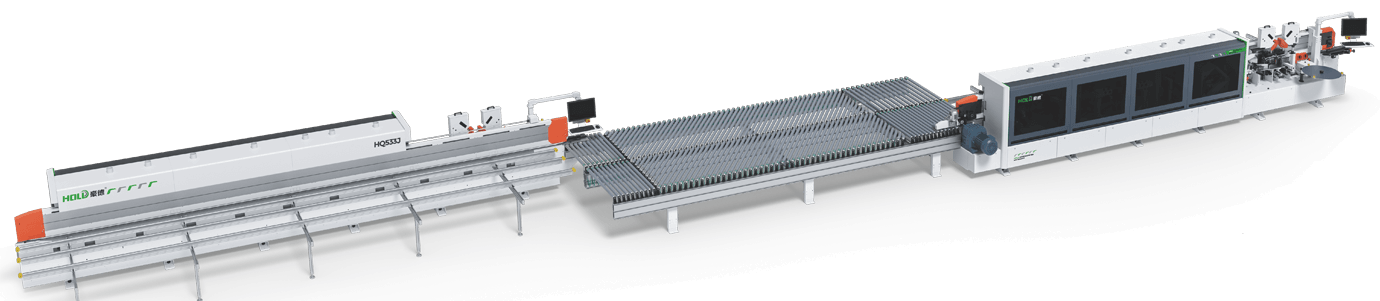

最薄上料可達9mm的板材(不可單張(zhang)取(qu)板)

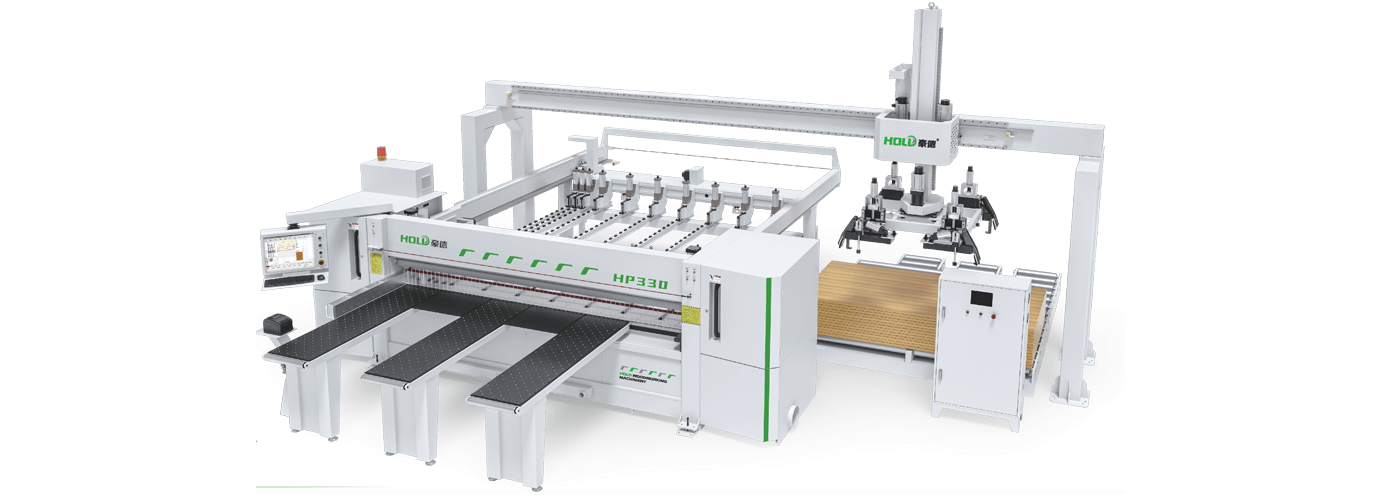

整線構(gou)成(cheng):龍(long)門(men)上料機+電腦裁板鋸(ju)

多點伺服抓板:解決因板材變形不易抓取問題

自(zi)動轉向(xiang)上料:可選擇縱向(xiang)或橫向(xiang)上料,提高板(ban)材(cai)出(chu)材(cai)率

龍(long)門抓手緩存:保(bao)證工作節拍高效穩(wen)定(ding),無縫銜接全工序

節省場地(di)空(kong)間:緊湊型結構設計,大幅度地(di)降低占地(di)面積

lt grasps the panels for feeding automatically, which reduces labor intensity and labor cosThe thinnest panel that can be grasped and feeded is 9mm(single panel cannot be taken).

Intelligent production line; the suction plate can automatically rotate so that the panels canbe feedied verticallyorhorizontally,

The whole line consists of Gantry feeding machine + oomputer panel saw.

Multi-point servo graspirng panels: soMves the problem of diffcult grasping aue to panels aeformation."

Automatic tuming feeaing panels: you can choose verical or horizontal fodng acordngly to improve the panelsutization.

Gantry machine gripper standby: ensure efficient and stable work thyhm, and seamlessly connect he whole proces.Save workshops space: compact structure design, greatty reduce the floor area.