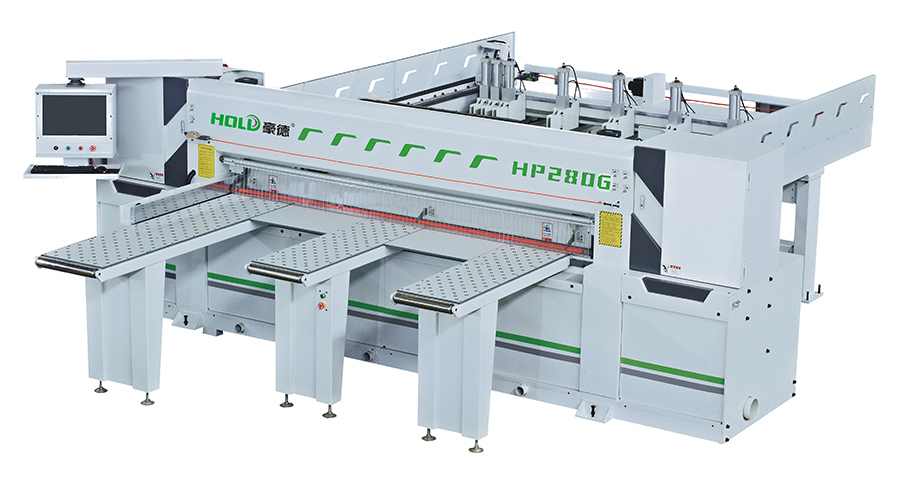

Electronic panel saw features the merits below:

1. Higher productivity

Automatic feeding is realized by the manipulator, which lowers the labor intensity and raises the production efficiency;

2. Longer service life

The service life is extended and the precision is better maintained due to a smaller friction coefficient and less wearing.

3. Woodworking panel saw enables a higher transmission efficiency and a lower friction loss.

The CNC panel saw features a smaller starting torque, more sensitive transmission and stable movement without any creeping phenomenon due to a smaller friction. It also has higher follow-up precision and positioning precision, and good synchronization.

Maintenance method of electronic panel saw:

1. Carry out the dust removal work inside the machine regularly based on the workload to ensure the normal heat dissipation of the motor.

2. Remove the dust on the sliding track regularly to ensure its stable and smooth operation.

3. Check the belt regularly and replace the worn timely if any.

4. Lubricate the necessary parts of the machine body regularly to ensure the stability and quietness of the equipment.

5. Regularly repair the saw blade.

6. Inject lubricants frequently and provide a suitable dust extraction system to reduce the invisible machine wearing by wood chips and dust.