Firstly, clean up the machine and work site; Secondly, check if the vacuum system is normal; Then check whether the sliding table saw blade is sharp; Check whether the saw blades in different sizes are in a straight line; Test the machine for about one minute to check whether the machine can run normally; Finally, prepare the materials and accessories.

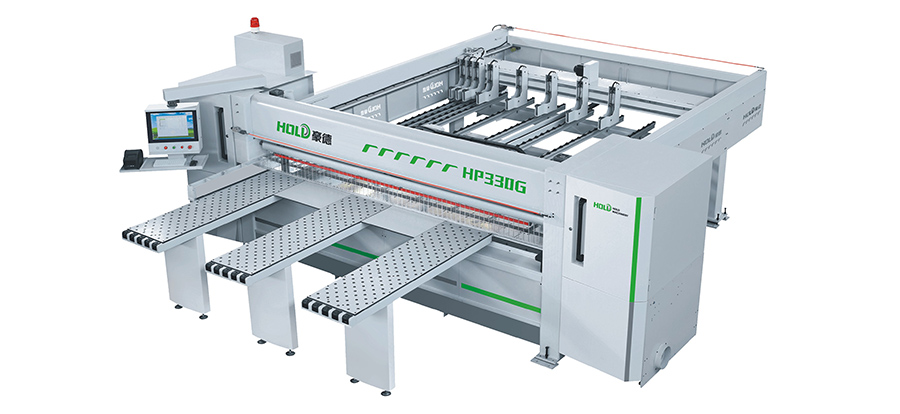

Start-up preparation of CNC panel saw

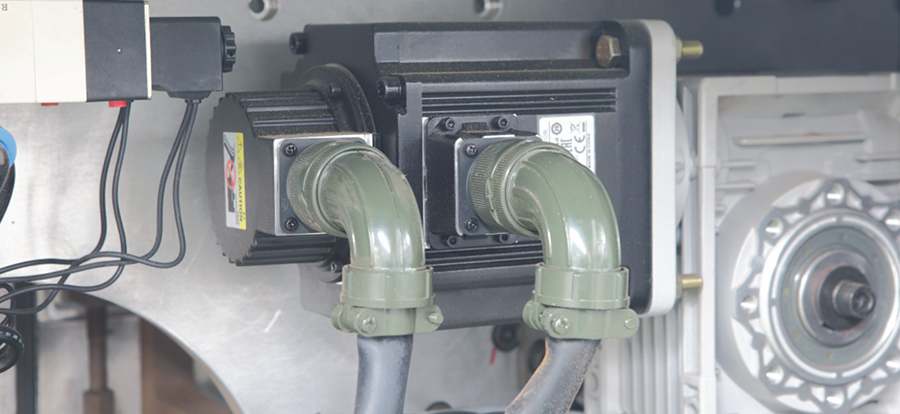

1. Check whether the power switch of the CNC panel saw is pushed at the right place, and whether the current loses a phase to avoid the machine motor burnout due to lack of phase when the machine is activated.

2. Clean the machine table and work place. When operating the CNC panel saw, the personnel start the machine must keep the legs and body straight, and can't bend over or lean against the operating platform.

3. Check whether the CNC panel saw blade is perpendicular to the sliding table, and whether the saw blades in different sizes are on a line. Test the machine for about one minute to check whether the CNC panel saw can run normally.

4. Push the manipulator a few times first, check whether the slide rails are unblocked, and keep the slide rails clean and smooth.

5. Prepare the materials and accessories.

As an indispensable equipment for batch-manufacturing, standardization, mechanization and professional production of furniture, CNC panel saw features simple operation, stability, safety and high efficiency The CNC panel saws produced in foreign countries and Shenyang are of more adaptability and stability for application, of which, the precision can meet the cutting requirements of solid wood and composite panels.